The full name of EN12159-2 is Load restraint assemblies on road vehicles – Safety – Part 2: Web lashing made from man-made fibres. This standard was approved by CEN (European Committee for Standardization) in 2000.

According to the CEN internal regulations, UK, France, Germany, Austria, Belgium, Denmark, Finland and other 12 countries are bound to implement this standard.

This standard specifies safety requirements for web lashing made from man-made fibres with flat woven webbings for multiple use and of lashing combinations with woven webbings for the safe surface transport of goods on road vehicles. And specifies methods for testing of web lashing for securing of loads.

Therefore, most of tie down strap manufacturers will follow the requirements of EN12195-2 for product production and inspection.

What are the key points of EN12159-2 safety requirements?

- At 1.25LC, all bearing parts of the complete tie down should have no evidence of deformation or other defects that affect the function. No seam failure shall occur.

- The strap elongation shall be not more than 7% at LC.

- A new unsewn textile strap shall sustain a tension force of at least 3LC.

- Min BF of complete web lashing shall be at least 2LC

- There shall be no sharp edges or burrs.

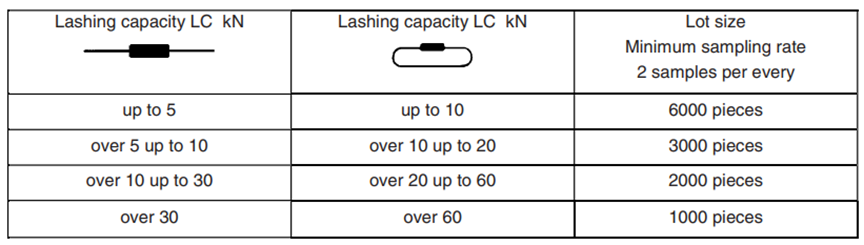

How to sampling for production test?

If a manufacturer who have no ISO QA system, then the sampling rates shall be as below table.

If a manufacturer who have ISO QA system, then the lot sizes listed in above table maybe doubled.

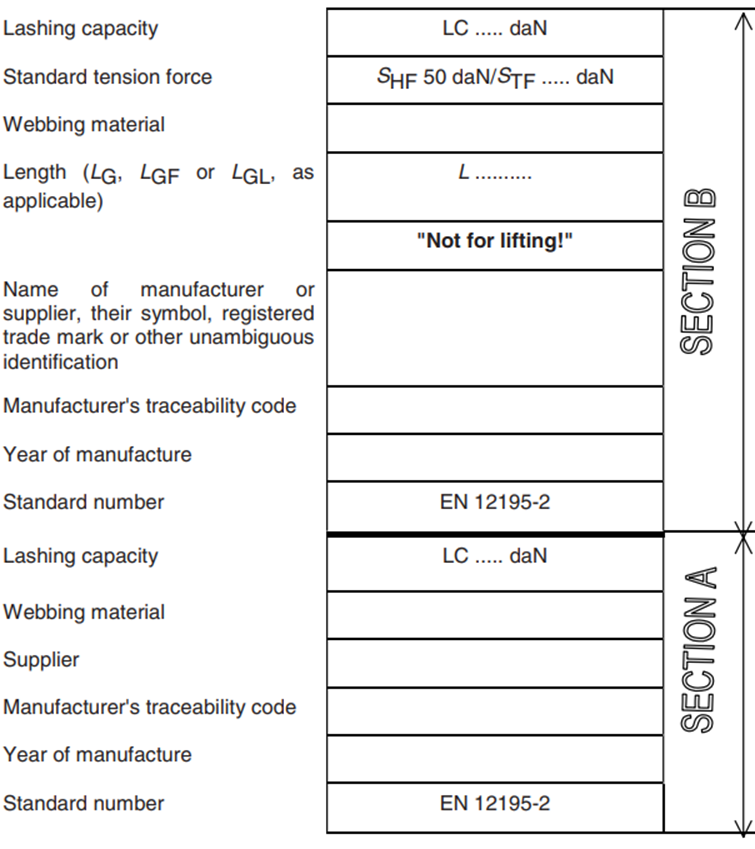

How to mark the label of a lashing strap?

For each complete lashing strap, if it is intended that parts be separable, should be marked with the following information if applicable on a label.

- lashing capacity LC;

- lengths LG, LGF and LGL in metre;

- standard hand force SHF;

- standard tension force STF (daN) or winch force;

- warning: “Not for lifting!”;

- material of strap;

- manufacturer’s name;

- traceability code;

- EN12195-2;

- year of manufacture;

- elongation at LC.

Below are some references of typical marking on label.

Label should have the following colors:

- blue: PES

- green: PA

- brown: PP

Key points of how to use the fastening belt safety.

- You should always use at least one pair of fastening belts to secure the stability of free-standing cargos.

- Before operation, you should always check if there is any tear, cut, nick, break and deformation in your belt or stitches; if there is any deformation, splits, pronounced sign of wear, corrosion in end fittings and tensioning devices.

- Check the tension force periodically in your journey, and prohibit any operation when the vehicle is in moving.

- The fastening belt should never be used when knotted.

- Be careful to the damages caused by sharp edges during transportation.

- When release the fastening belt, you should make sure that the stability of the load is independent of the fastening belt and that the release should not cause the load to fall of the vehicle.