You can find a lot of different tie down straps in the market. But do you really know the exact differences of them?

A tie down strap mainly include three parts. They are metal ratchet/cam buckle, woven strap and hooks. Then what aspects do we need to evaluate for a good tie down strap?

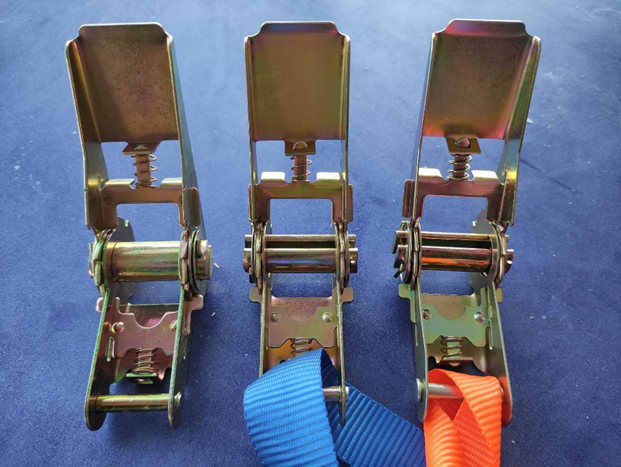

1. Metal ratchet/cam buckle

When you have 2 different Tie down straps in front of you, you can’t find many differences from appearance. But when you go into the details about metal ratchet/cam buckle, such as the overall dimension, the thickness of metal plate, the number of convex teeth, the central axis, etc. After comparison, you can have a sense about which is better. In general, the thicker, the better. With more convex teeth, then it will be smoother in operation.

Keep in mind that another important thing is about the metal material. Mild steel is normal, manganese steel and stainless steel are also applied for some product. You should also ask your supplier if the metal ratchet/cam buckle has been heat treated and has what kind of surface treatment.

2. Woven strap

Woven strap is normally made of PES(Polyester), or PP(Polypropylene) or PA (Polyamide, Nylon).

From the quality point of view, Nylon is best, PES is little big better than PP. But from cost point of view, price of PES and PP’s are in a similar level, and they are almost half of Nylon’s. So, PES is the most cost-efficient material compared to the other two. But one thing you have to make sure is that is the material new or recycled?

From the woven point of view, ordinary weaving and reinforced weaving also bring you different quality.

It is not correct to select a Tie Down Strap only because it looks more thicker and stronger. Density of PES is 1.33g/cm ³, it is higher than PP 0.91g/cm³, and PP fiber has more weft threads when weaving. With these facts PP looks more thicker and stronger. But in fact, the thinner PES strap provides same lashing capacity.

3. Hooks

Quality of hooks is depending on material, hook size and diameter.

Normal material of hook includes low-carbon steel and medium-carbon steel. Some supplier will do heat treatment for it but the others not. Of course, the hooks after heat treatment has better strength.

Some hooks have dipped coat. You should know if is it eco-friendly or not.

In additional, a handle with good look, fashion and new style will influence your purchasing decision too. But it is no doubt that it comes with higher price.

In summary, although 2 different tie down straps looks similar, but their material, size and construction will cause big difference in price. As a non-professional consumer, lashing capacity and breaking force are the things you need to clear know in first when you are going to buy a tie down strap. Lashing capacity is safety working load. It is half of breaking force in normal cases. You can get more guarantee if you can see a GS certification or AS certification on product package. If you are a professional buyer, you should request documents of production process, quality control process and capacity testing record from your supplier.

For more information, please send mail to james@ql-tools.com.